Everything you need to know about bespoke rooflights.

Bespoke rooflights, otherwise known as custom-made skylights, are custom-made and manufactured to the specific measurements of your home or commercial building. They can be as big or as small as you need them.

Here at Lonsdale Metal, we specialise in bespoke rooflights and have manufactured overhead glazing systems for structures like Windsor Castle, Kings Cross Railway, and even for the private homes of Prince Edward and Countess Sophie of Wessex.

Established in 1946, we have some of the most highly-experienced architects available to help you with your every need. We have many variations of bespoke rooflights for sale.

This article will tell you everything you need to know and provide you with the knowledge to start making steps towards installing your Bespoke Rooflight.

Do you know what kind of glass you want?

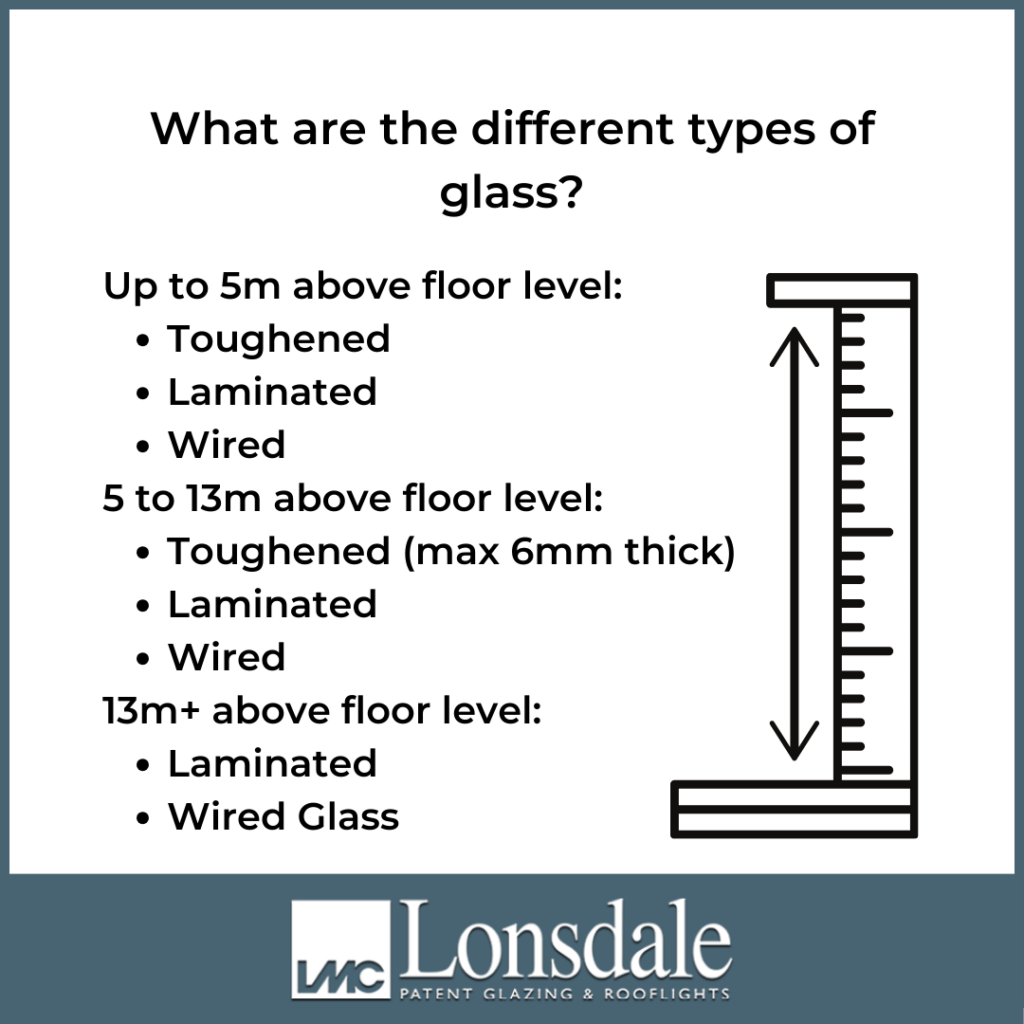

There are lots of different types of glass available to create your Bespoke Rooflight, so you must consider the role of your skylight and the effects that may have on your decision.

Only certain types of glass are suitable for overhead glazing, as the way they shatter could pose a hazard. Toughened glass (for example) is heat treated. This means that if the glass shatters: it will do so into small fragments that might be difficult to recover if the skylight is placed over a swimming pool (for example).

This will not pose a safety risk, per-se, it will just make the clean-up a lot more difficult. This is why it’s not suitable in environments that would already make clean-up harder.

Any bespoke rooflights installed upwards of 13 metres high should only be made with laminated or wired glass. This is because laminated glass is made of two sheets of glass bonded with an interlayer that is normally between 0.4-0.8mm thick. This kind of glass isn’t invincible by any means, but if it does crack, the interlayer will keep it together. This is the same kind of glass used for walkways and car windshields.

Laminated glass is normally 6.4mm-6.8mm thick to ensure that it won’t break under the pressure of the elements. To find out more about the different types of glass, visit our Technical Design Considerations page.

Have you considered Thermal Insulation?

We have low-emissivity options available in the form of coating that only allow 35% of the sun’s heat to be absorbed by the building. It is now possible to create glass with centre pane U values of 1.0W/m2.K for double glazing and 0.60W/m2.k for triple glazing.

Additionally, our neutral solar control glass allows 70% light transmission and complies with the Building Regulation requirements.

Pitch is important.

At Lonsdale Metal, we recommend a minimum pitch of 15°, as the glass will almost clean itself. This angle allows debris and dirt to slide off the pane and stop it from settling.

If you choose to install a bespoke rooflight under the recommended pitch angle, you need to ensure that the systems are certified for installation to avoid the risk of water ingress.

What about walk-on requirements?

The glass you use must have been reinforced so it isn’t dangerous to walk on. You can ensure this by having a risk assessment conducted to determine whether there is a risk of injury.

If it is determined that there is a health risk, you should notify us before we install your rooflight and ensure that the necessary health and safety procedures are implemented.

Do you need ventilation?

If you don’t have air conditioning and require ventilation, it is possible to have opening vents added on to a bespoke rooflight that can be operated manually or electrically, depending on your needs. Additionally, it is not difficult to include automated opening and closing, as well as a rain sensor.

Don’t forget about maintenance.

For anything to keep working as it should, it should be maintained regularly. We at Lonsdale Metals recommend that you have your bespoke rooflight and glazing system inspected once a year, referring to a maintenance checklist so that nothing is forgotten.

If there are a lot of chemicals in the building, they could affect the functions of the system, so it should be assessed every 4-6 months rather than a year, depending on how severely the chemicals could affect it.

The glass should be cleaned every six months with soft cloths and mild detergents to stop it from looking scummy and foggy. The use of jet washers would be inappropriate, as they could damage the surface finish or seal around the product and allow for leaking.

Bespoke rooflights encourage energy efficiency.

Buildings that have a 15-20% rooflight area will cut energy usage and reduce CO2 emissions. This is because much less energy will be used to light the area. After all, all of the light is naturally generated.

Also, sunlight and the Vitamin D it contains directly correlates with serotonin levels, which helps to cause an elevated mood.

If you’d like to learn more about Bespoke Rooflights, and make an enquiry, visit our Contact Us Today page.